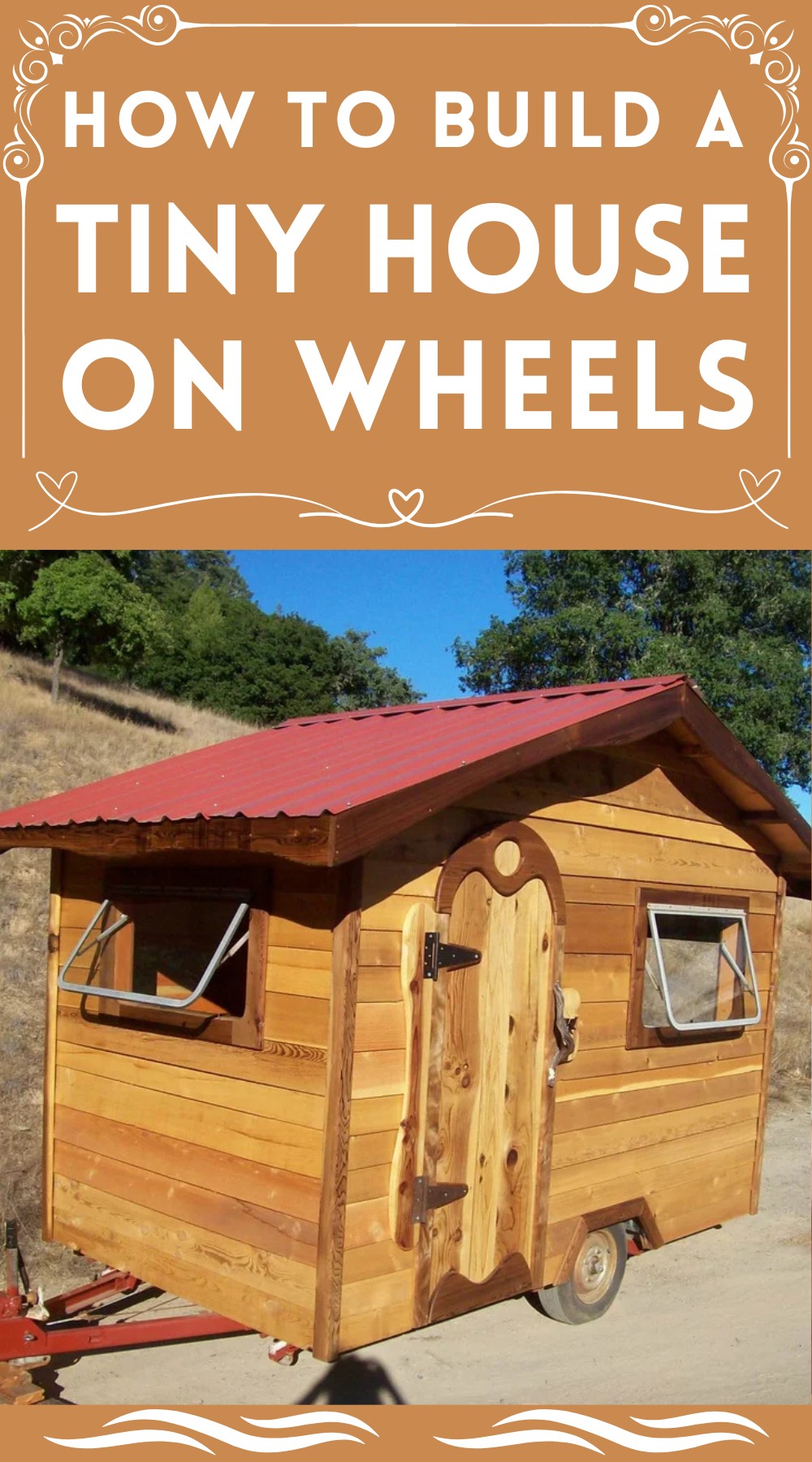

Learn how to build a sustainable, eco-friendly tiny house using reclaimed materials following our step-by-step guide. It will be the best project that leads you to make a cozy, minimalistic home affordably.

How To Build A Tiny House

Our guide will help you make this small house from reused stuff. It’s a cool project that saves money and helps nature, too. Plus, every old piece you use adds charm and makes your tiny home unique. So, be ready to start this fun project that gives back to the environment and surely thank me later.

Materials List

Frame Preparation:

- Old trailer frame

- Rusty metal primer

- Quality metal paint

Flooring:

- Rough-milled redwood 1x6s

- 1/8 inch plywood pieces (for protection)

Wall Framing:

- Rough cut 2x2s

- 3-inch star drive screws

Roof Framing:

- 1×3 rafters

- 1×2 framing for the trusses

Siding:

- 1/8 inch plywood sheets

- Narrow gauge staples

Exterior Siding:

- Rough-milled cedar and fir boards (~1/4 inch thick)

Insulation and Interior Siding:

- Recycled blue jeans insulation

- Beautifully planned boards for interior siding

Windows and Door:

- Reclaimed aluminum windows

- Old-growth redwood, cedar, fir, and redwood thin boards for the door

Roofing:

- 1/2-inch plywood sheets

- Metal roofing material

Trimming:

- Quartered 3-inch fir tree

- Old-growth redwood for trimming

Tools Used

- Angle grinder

- Drill with a wire wheel and brushes

- Compressed air staple gun

- Planer and edger (for wood preparation)

- Sawzall and handsaw (for cutting)

- Finish nailer

Step-by-Step Guide

Preparing the Frame

- Demolition: Start with an old trailer frame, removing any existing structures and materials like aluminum (which can be recycled) and preserving the plywood floor for reuse.

- Cleaning: Employ an angle grinder and a drill outfitted with wire attachments to scrub away old paint and rust, ensuring the frame’s integrity isn’t compromised by corrosion.

- Priming and Painting: Apply a rusty metal primer followed by a coat or two of quality metal paint to protect the frame from future rust.

The Floor

- Material Acquisition: Source rough-milled redwood 1x6s, ideally from a local provider.

- Preparation: Process the boards through a planer and edger to achieve a flat and smooth surface.

- Installation: Secure the floorboards from underneath with screws to avoid visible fasteners, and cover the finished floor with plywood pieces for protection.

Framing the Walls

- Selecting Wood: Opt for rough cut 2x2s for an authentic, variable aesthetic.

- Assembling: Use 3-inch star drive screws for robust framing, accommodating for the natural inconsistency in wood size.

- Window Placement: Install windows in three walls, leaving one wall solid for structural integrity and to maintain privacy.

Framing the Roof

- Structural Choices: Given the climate, choose lighter materials like 1x3s for rafters and 1x2s for trusses, supporting a movable yet sturdy design.

- Lightweight Construction: Strategically use various wood sizes to reduce weight without sacrificing strength.

Siding With 1/8 Inch Plywood

- Application: Cover the frame with plywood for added rigidity, cutting the sheets to fit as necessary.

- Fastening: Use a compressed air staple gun for quick and secure attachment of the plywood sheets.

Lap Siding

- Choosing Siding: Staple on rough milled cedar and fir boards, varying their width for a natural look and ensuring overlap to conceal the staples.

Insulation and Interior Siding

- Insulation: Use recycled blue jeans insulation for even distribution and better handling compared to fiberglass.

- Interior Walls: Select knot-free boards, process them for aesthetic appeal, and attach them as interior siding with a finish nailer.

Windows and Door

- Windows: Adapt and repurpose the trailer’s old aluminum windows to fit the wooden structure.

- Door: Construct a rounded door from a combination of redwood, cedar, and fir boards for a softer look amidst the tiny house’s straight lines.

Roofing

- Coverage: Lay 1/2 inch plywood over the rafters, extending it for a significant overhang to protect the house’s exterior.

- Material: Opt for metal roofing cut to size, ensuring durability and weather resistance.

Trimming It All Out

- Finishing Touches: Utilize natural wood for corner trimming and detail work around the house, giving priority to aesthetics and material integrity.

Finished!

Enjoy the satisfaction of living in your own made home, reveling in a structure born from hours of dedication and a commitment to sustainable living. With approximately $1,500 in raw materials and countless hours of toil, you can easily make your tiny house that stands ready to charm, provide shelter, and inspire further creative endeavors.

How Ventilation And Waterproofing Your Tiny House Can Be Beneficial?

Integrating effective ventilation and waterproofing into your tiny house project is vital; it not only safeguards the structure’s longevity by preventing moisture entrapment and mold but also ensures a healthy and comfortable living environment. Proper ventilation helps regulate indoor air quality and humidity while comprehensive waterproofing shields against leaks and weather-related damage, preserving the integrity and warmth of your tiny dwelling.

These measures, though often overlooked, are foundational to the functionality and durability of a tiny house, making them a beneficial investment in both the short term and for years to come.

Leave a Reply